Understanding Metal Perforated Plates Applications and Benefits

Metal perforated plates have become an essential component in various industries due to their versatile functionality and distinctive aesthetic appeal. These plates are thin sheets of metal that have been punctured with holes of various sizes, shapes, and patterns. The perforation process not only provides unique design possibilities but also enhances the material properties of the metal. In this article, we will explore the composition, applications, and benefits of metal perforated plates.

Composition and Manufacturing

Metal perforated plates can be made from a variety of metals, including stainless steel, aluminum, brass, and carbon steel. The choice of material often depends on the specific application and required properties, such as corrosion resistance, strength, and weight. During the manufacturing process, sheets of metal are fed into a machine equipped with punch dies that create the desired hole patterns. The holes can vary in diameter and spacing, allowing for customization to meet specific needs.

The perforating process can also include additional techniques such as bending, rolling, or cutting, which further enhance the plates' applications. The finish of these plates can range from smooth to textured, and they can be coated or painted to improve durability and aesthetics.

Applications of Metal Perforated Plates

The applications of metal perforated plates are diverse and span multiple industries

1. Construction and Architecture Perforated plates are widely used in architectural designs for facades, ceilings, and wall partitions. The ability to customize hole patterns makes them ideal for aesthetic design while allowing light and air to pass through.

2. Industrial Filtration In many industrial processes, perforated plates serve as filters. They prevent the passage of large particles while allowing smaller particles or fluids to flow through, making them essential in wastewater treatment and chemical processing.

3. Acoustic Panels In spaces requiring sound control, perforated plates can be utilized as acoustic panels. The holes can help absorb sound waves, improving the sound quality within a room or open space.

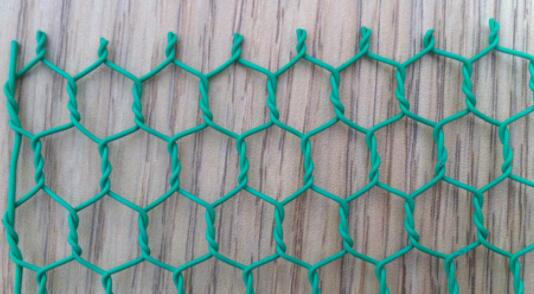

4. Safety and Security Many safety applications involve perforated plates. Grills, barriers, and fencing made from perforated metal provide visibility while still offering security and protection from unauthorized entry.

metal perforated plate

5. Home Decor In interior design, metal perforated plates can be used for decorative purposes. They can be found in light fixtures, room dividers, and furniture, creating a modern and stylish appearance.

6. Automotive and Aerospace The automotive and aerospace industries use perforated plates for lightweight structures that also provide strength and rigidity. This reduces the overall weight of vehicles and aircraft, improving fuel efficiency and performance.

Benefits of Using Metal Perforated Plates

The advantages of integrating metal perforated plates into various applications are extensive

- Versatility With multiple materials, hole sizes, and patterns available, perforated plates can be tailored to meet a wide array of requirements for different industries.

- Enhanced Performance Perforated plates can improve airflow, drainage, and filtration, making them highly functional in both industrial and commercial settings.

- Aesthetic Appeal The unique patterns and finishes available in perforated plates offer significant design flexibility, allowing architects and designers to create visually appealing structures.

- Lightweight Compared to solid metal sheets, perforated plates are significantly lighter while still maintaining structural integrity, which is advantageous in construction and manufacturing applications.

- Cost-Effectiveness In many cases, the use of perforated plates can be more cost-effective than other materials or methods due to their multifunctionality and ease of installation.

Conclusion

Metal perforated plates are indispensable resources across a multitude of sectors. Their combination of aesthetic versatility, functional benefits, and cost-effectiveness makes them a favorable choice for architects, engineers, and designers alike. As technology advances, the potential for innovative uses and designs featuring perforated plates will continue to grow, ensuring their relevance in contemporary applications. Whether for industrial use, architectural design, or decorative elements, metal perforated plates will remain a fundamental aspect of modern engineering and design.