Understanding the Importance of 1% 204 Mesh Screen Applications and Benefits

In various industries, the necessity for effective separation and filtration methods cannot be understated. One such solution that has gained significant traction in recent years is the 1% 204 mesh screen. This specific type of mesh offers a unique balance between filtration efficiency and durability, making it an ideal choice for numerous applications ranging from construction to food processing.

What is a 204 Mesh Screen?

Before delving into the specifics of a 1% 204 mesh screen, it’s essential to understand what a 204 mesh screen entails. The term mesh refers to the number of openings per linear inch of the screen. In this case, a 204 mesh screen has 204 openings in each inch of the fabric. This translates to a screen that is capable of filtering out particles of a certain size while allowing smaller particles and fluids to pass through.

The 1% aspect typically refers to the percentage of the material that can be filtered out, indicating its efficiency in separating larger particles from smaller ones. The mesh can come in various materials such as stainless steel, nylon, or polyester, each offering its own set of benefits based on the application's demands.

Applications of 1% 204 Mesh Screen

The versatility of a 1% 204 mesh screen makes it applicable in multiple fields

1. Food Industry In food processing, maintaining cleanliness and quality is paramount. A 1% 204 mesh screen is often used to filter out contaminants from liquids such as juices, oils, and sauces. Its fine mesh allows for a thorough purification process, ensuring that the final product meets safety standards without compromising on quality.

2. Water Treatment Effective water filtration is crucial in environmental management. A 1% 204 mesh screen can be employed in various stages of water treatment to remove sediments and larger particulate matter, thus ensuring cleaner water is delivered to consumers. The robustness of the screen allows for repeated use in harsh environments, addressing the challenges faced in water treatment facilities.

3. Pharmaceutical Industry In pharmaceutical manufacturing, the purity of ingredients is essential. A 1% 204 mesh screen helps to ensure that active pharmaceutical ingredients are free from impurities. The mesh can also be used during the packaging process to guarantee consistency and safety.

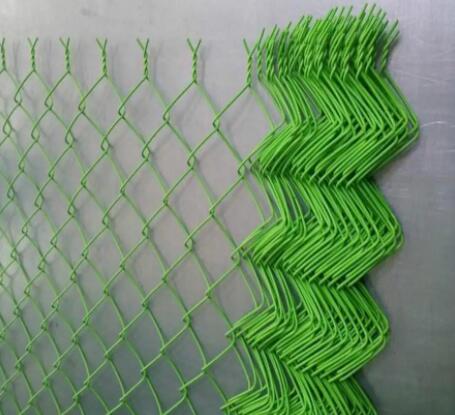

1 4 mesh screen

4. Construction Materials In construction, a 1% 204 mesh screen can be used in concrete mixing, helping to maintain consistency in the materials used. By filtering aggregates, the screen ensures that only the right particle sizes are utilized, improving the overall strength and durability of the constructed body.

5. Mining and Mineral Processing The mining industry utilizes 1% 204 mesh screens for sorting and separating minerals. The precision of the mesh allows for the efficient extraction of valuable minerals while discarding waste materials.

Benefits of Using a 1% 204 Mesh Screen

1. High Filtration Efficiency The primary benefit of using a 1% 204 mesh screen lies in its ability to filter out a significant percentage of unwanted particles. This high efficiency leads to cleaner end products across various industries.

2. Durability Manufactured from robust materials, a 1% 204 mesh screen can withstand harsh chemical exposures, temperature fluctuations, and physical strain without losing its structural integrity. This durability ensures a long service life, reducing the need for frequent replacements.

3. Cost-Effectiveness Although the initial investment may be higher, the longevity and performance efficiency of a 1% 204 mesh screen can lead to savings in operating costs over time. With less need for replacement and maintenance, businesses can allocate their budgets more efficiently.

4. Versatility With applications across diverse sectors, a 1% 204 mesh screen offers flexibility for businesses looking for one solution that can cater to various filtration needs.

5. Improved Quality Control Utilizing a 1% 204 mesh screen enables businesses to maintain high-quality standards in their products. Whether in food production or pharmaceuticals, ensuring product quality can significantly impact consumer satisfaction and corporate reputation.

In conclusion, the 1% 204 mesh screen is a vital tool that facilitates effective filtration across multiple industries. Its efficiency, durability, and versatility make it a preferred choice for businesses aiming to enhance their operational practices and product quality. As markets evolve and technological advancements continue, the significance of such filtration solutions will undoubtedly expand, driving innovation and quality across sectors.