Understanding Wire Screen Material Applications and Benefits

Wire screen materials, also known as wire mesh or wire cloth, serve as fundamental components in various industries due to their versatility and functionality. This article aims to explore the types, applications, and advantages of wire screen materials, highlighting their significance in modern manufacturing and construction processes.

Types of Wire Screen Materials

Wire screen materials are primarily classified based on the material from which they are made, the mesh size, and the weaving pattern. The most common materials include

1. Stainless Steel Highly resistant to corrosion and oxidation, stainless steel wire screens are ideal for environments that require durability and hygiene, such as food processing and pharmaceutical industries.

2. Aluminum Lightweight and resistant to rust, aluminum wire mesh is often used in applications where weight is a concern, such as in the aerospace or automotive sectors.

3. Brass and Bronze These materials are commonly used in decorative applications due to their aesthetic appeal. They also possess decent resistance to corrosion, making them suitable for outdoor furnishings and architectural details.

4. Fiberglass Non-metallic wire screen material, fiberglass is resistant to rust, making it ideal for applications in environments that have high moisture levels.

Each of these materials can be configured in various mesh sizes, which affects the filtration capabilities of the screen. The weaving patterns, such as plain weave, twill weave, and Dutch weave, further define the properties and uses of the wire screen.

Applications of Wire Screen Materials

Wire screen materials are found across numerous sectors due to their flexibility and utility. Some notable applications include

1. Filtration Wire screens are primarily used in filtration systems to separate solids from liquids. Industries like chemical processing, water treatment, and oil refining utilize these screens to ensure purity and quality in their end products.

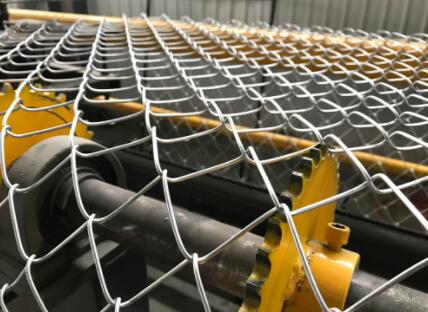

wire screen material

2. Construction In construction, wire mesh is employed to reinforce concrete and provide structural integrity. It can be found in roadworks, bridges, and buildings, ensuring that they withstand significant loads and pressures.

3. Catering and Food Service Stainless steel wire screens are used extensively in kitchens for food preparation and cooking. They are easy to clean and sanitize, contributing to food safety and compliance with health regulations.

4. Security and Safety Wire screens are also used as security panels, offering protection against intruders and debris. They are commonly installed in windows, doors, and fencing to enhance safety without obstructing visibility.

5. Aerodynamics and Acoustic Engineering In specialized industries such as aerospace and automotive, wire mesh is used for aerodynamics and sound dampening. Its properties allow for balanced airflow while reducing noise levels in confined spaces.

Benefits of Using Wire Screen Materials

The use of wire screen materials comes with a myriad of benefits

- Durability Wire screens made from stainless steel or other sturdy materials offer long-lasting performance, even in challenging environments.

- Versatility With various materials, sizes, and weaving patterns available, wire screens can be customized to meet specific application requirements.

- Cost-Effective With their reusable nature and easy maintenance, wire screen materials can be a cost-effective choice for many industries.

- Safety and Compliance Wire screens help maintain safety standards by ensuring compliance with health regulations, especially in food and pharmaceutical industries.

Conclusion

In conclusion, wire screen materials play a crucial role in a multitude of industries ranging from construction to food safety. Their versatility, durability, and cost-effectiveness make them invaluable to processes that demand high levels of performance and safety. As technology advances and new applications are discovered, the significance of wire screen materials is likely to grow, reinforcing their place in modern manufacturing and construction practices. Understanding their various types and benefits can help organizations make informed choices to optimize their operations and enhance productivity.