annealed iron

Latest articles

2. Drying: Dry the washed steel wire through hot air or other drying equipment to remove water.

annealed iron...

annealed iron 【annealed iron】

Read More

annealed ironAs we all know, the use of hexagonal net protection, can protect the natural environment while protecting the bridge, so as not only to green the ecological environment, but also to prevent soil erosion.

...

annealed iron 【annealed iron】

Read More

annealed ironPeople who want to keep birds for the long term need to know how to choose the right cage and how to raise them scientifically. It’s all about the birds’ daily life and health. Only by knowing more about the various aspects of raising birds can they be raised healthy and lively, singing freely and suitable for viewing.

...

annealed iron 【annealed iron】

Read Moreannealed iron

...

annealed iron 【annealed iron】

Read Moreannealed iron

...

annealed iron 【annealed iron】

Read Moreannealed iron

...

annealed iron 【annealed iron】

Read Moreannealed iron

...

annealed iron 【annealed iron】

Read Moreannealed iron

...

annealed iron 【annealed iron】

Read MoreOnce you find that the beginning of it has deformation, rust or broken problems must be timely correction. Generally speaking, the blade barbed rope will not be damaged simply, but it cannot be ensured that it will not happen. Because the local place where the blade barbed rope is required is generally outdoors, the probability of presenting an incident will be greatly increased. For example, in the plantation under the hillside, the blade barbed rope was damaged and deformed by stones rolling down the mountain, which requires manual correction in time, otherwise the deformed blade barbed rope will not only affect the beauty, but also lay hidden dangers for safety.

annealed iron...

annealed iron 【annealed iron】

Read Moreannealed iron

...

annealed iron 【annealed iron】

Read More

Popular articles

- Galvanized wire to galvanized evenly, a body is now its cross section, the second is the longitudinal uniformity. In the actual operation process, such as the jitter of steel wire, the surface scum in the plating pot and other reasons will cause the accumulation of galvanized layer on the surface of galvanized wire, and efforts should be made to solve the problem.

- Deoxygenation of boiling steel is incomplete, oxygen content is high, phosphorus and other impurities distribution is uneven, local overspending, aging sensitivity and cold brittle sensitivity are high, hot cracking tendency is added. If unqualified electrode is used, if the content of carbon and sulfur in the weld metal is too high, cracks will occur. For example, when factories use acidic electrodes to weld Q235-A steel, the high carbon fernoganese in the electrode coating will lead to thermal cracks in the weld.

Continuous production does not need heating, but needs cooling. Cooling can be in the groove side row thin wall plastic pipe, through the flow of tap water cooling, can also be used as a titanium pipe temperature control device. In the process of composite electroplating galvanized wire, the plating solution must be stirred to obtain the composite coating in which the particles dispersed in the matrix metal. Stirring methods include mechanical stirring, air stirring, ultrasonic stirring, bath circulation, etc.

Latest articles

-

Post time: 13-12-22 -

-

A barbed rope is literally a kind of barbed rope. Generally speaking, the material is made of iron wire or copper wire. People have a very long history of using barbed ropes, as early as the 19th century Americans began to use the first barbed ropes. Function: Its first function is agricultural fence. The origin of the thorn rope is in agriculture. People used the thorn rope to divide the fields into different pieces. Barbed wire is also widely used in fencing until now. Secondly, it is used for protection and protection. For example, people put barbed ropes around the walls of their houses to prevent people from climbing over the walls and entering the yard. There are many other functions such as fire prevention and theft prevention.

-

-

Post time: 01-08-22 -

The error of construction welding net diameter should be controlled at 0.02 mm. For example, we buy wire diameter of 89 wire welding net, with a micrometer to measure the diameter, the diameter of the allowable range is 87 -91 wire. In this range is qualified welding net. Because the accuracy has been compared, but no one can control it so well in the production process. The welding net can be accurate to 0.01 mm, so the error is allowed.

Links

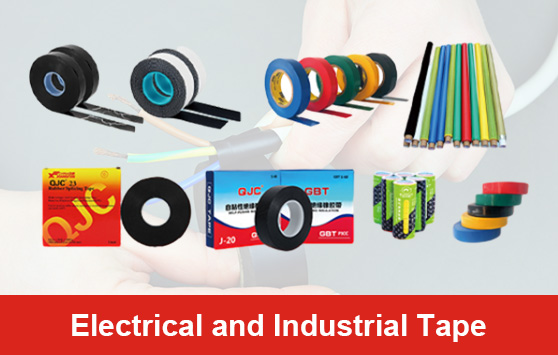

- High-speed splicing tape, as the name suggests, is designed for rapid and seamless joining of materials during manufacturing processes. It is engineered with advanced adhesive technology, allowing it to bond instantly and securely, even under high-speed conditions. This not only enhances productivity but also minimizes downtime, thereby boosting overall operational efficiency.

In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar

In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar In aerospace, it's vital for ensuring the safety and reliability of wiring systems in aircraft engines and avionics, where temperatures can soar high temp electrical tape. For industrial applications, it's commonly employed in welding, HVAC systems, and furnace repairs, providing insulation and protection against sparks and intense heat.

high temp electrical tape. For industrial applications, it's commonly employed in welding, HVAC systems, and furnace repairs, providing insulation and protection against sparks and intense heat.Single Phase Start Control Box

For users looking to maintain a certain look or to blend repairs into dark-colored surfaces, this tape offers an excellent choice For users looking to maintain a certain look or to blend repairs into dark-colored surfaces, this tape offers an excellent choice

For users looking to maintain a certain look or to blend repairs into dark-colored surfaces, this tape offers an excellent choice For users looking to maintain a certain look or to blend repairs into dark-colored surfaces, this tape offers an excellent choice black flex seal tape.

black flex seal tape.The construction industry also benefits from the versatility of black insulation tape. It is commonly used in marking safety zones, securing tarps, and even bundling tools or equipment. The durable nature of the tape allows it to withstand various environmental conditions, making it an essential item in any contractor's toolkit. Furthermore, its ease of use means that workers can make quick adjustments or repairs on the go, saving time and reducing project delays.

In warehouses and factories, heavy duty floor tape plays a vital role in creating organized and safe work environments

. It can be used to mark aisles, designate parking spots for machinery, and indicate where equipment or materials should be stored. By clearly marking these areas, accidents and confusion can be minimized, leading to increased efficiency and productivity.heavy duty floor tape

What Are the Types of Polyethylene Tape?

Sensors provide your control box with real-time data on essential conditions such as operating pressure and temperature. This information plays an enormous role in helping your controller execute its primary functions. Commonly utilized sensors include;

Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes

Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes 130c linerless rubber splicing tape. This not only streamlines production but also enhances productivity.

130c linerless rubber splicing tape. This not only streamlines production but also enhances productivity.7. Easy to use: a layer of Self Fusing tape can play a good insulation role and reduce labor and cost.

Features and Benefits

There are several types of polyethylene film, each with a different density and use. Polyethylene tape is categorized by the tape’s density:

3m amalgamating tape. This not only enhances the overall integrity of the filling but also helps to reduce the risk of post-operative sensitivity.

3m amalgamating tape. This not only enhances the overall integrity of the filling but also helps to reduce the risk of post-operative sensitivity.These are heavy-duty control boxes engineered with sophistication to meet the complex demands of industrial systems. They are primarily used to automate heavy machinery in industrial applications such as manufacturing and waste management. Industrial control boxes feature additional components such as cooling units, which equip them to withstand harsh conditions.

By designating specific routes for foot traffic, workers can move more efficiently and safely through the workplace By designating specific routes for foot traffic, workers can move more efficiently and safely through the workplace

By designating specific routes for foot traffic, workers can move more efficiently and safely through the workplace By designating specific routes for foot traffic, workers can move more efficiently and safely through the workplace yellow safety floor tape. This is particularly useful in large facilities where there may be multiple exits, machinery, and other obstacles. By following the designated paths, workers can reduce the risk of collisions and other accidents.

yellow safety floor tape. This is particularly useful in large facilities where there may be multiple exits, machinery, and other obstacles. By following the designated paths, workers can reduce the risk of collisions and other accidents.Its high shear strength makes window glazing tape a good option for mounting on vertical surfaces. It has good resistance to humidity, acid, oils, and grease. As a polyethylene foam tape, it has excellent conformability, even conforming to rough or uneven surfaces.