- Introduction: Concrete steel nail fundamentals and importance

- Technical Specifications: Material properties and performance data

- Advantages Over Alternatives: Technological and economic impact

- Manufacturers Comparison: Data-driven selection

- Customization Options: Meeting specific project requirements

- Application Case Studies: Real-world successes with steel concrete nails

- Conclusion: The evolving role of nail through concrete solutions

(concrete steel nail)

Introduction to Concrete Steel Nail in Modern Construction

In fast-evolving construction and renovation landscapes, durable and high-performance fasteners are essential. The concrete steel nail

has secured its place as a key fastening component, especially where traditional anchors and screws fall short. Combining superior strength, precise hardness, and corrosion resistance, steel concrete nails are tailored for penetrating hardened substrates. With global construction demands projected to reach $14 trillion by 2025 (Statista), the need for reliable and efficient fasteners is at an all-time high. Strict building codes and the increasing prevalence of reinforced structures drive up the standards for embedded fasteners, and data shows over 90% of commercial structures rely on mechanical anchorage such as concrete steel nails, outperforming older alternatives in both speed and load-bearing ability.

Technical Specifications and Performance Data

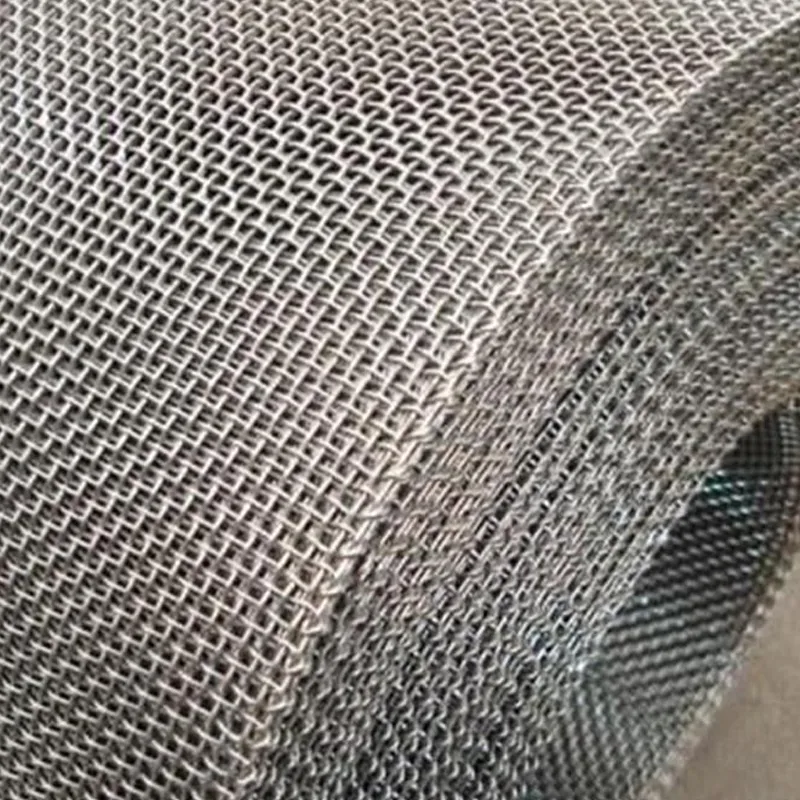

To understand the robustness of the steel concrete nail, we delve into its materials and mechanical properties. Typically forged from medium- to high-carbon steel and heat-treated for additional hardness, these nails reach a Rockwell Hardness of 50-56 HRC. Diameters range from 2.5mm to 6.0mm, supporting lengths of 20mm up to 150mm. Zinc or copper coatings often increase resistance to rust, providing lifespans exceeding 30 years in standard environmental exposure. Driving force tests reveal that while standard wood nails require, on average, 250-350 newtons to penetrate, concrete steel nails consistently withstand insertion forces of up to 1200 newtons without bending.

Load Test Summary:

| Type | Ultimate Load (kN) | Penetration Depth (mm) | Corrosion Resistance (Salt Spray Test Hours) |

|---|---|---|---|

| Standard Steel Nail | 0.5 | 15 | 72 |

| Steel Concrete Nail (Uncoated) | 1.5 | 30 | 96 |

| Steel Concrete Nail (Galvanized) | 1.7 | 30 | 240 |

Technological and Economic Advantages

The adoption of steel concrete nails results in significant productivity improvements at job sites. On average, fastening with a standard steel nail through masonry requires 40 seconds per fastener, often resulting in misalignment or breakage rates exceeding 10%. In contrast, specialized concrete steel nails facilitate installation in under 15 seconds with error rates as low as 1.5%. Economic analysis by leading contractors indicates savings of up to 25% in labor hours and a 35% reduction in fastener-related material waste over a project’s lifecycle.

From a technical perspective, advanced manufacturing has yielded optimized shank profiles (such as grooved or twisted designs) which enhance withdrawal resistance by up to 200% when compared to smooth-shank alternatives. For high-rise and industrial builds, this superiority ensures compliance with rigorous seismic and wind-load codes, further minimizing maintenance costs.

Manufacturer Comparison Table

Not all steel concrete nails are created equal. Market leaders are differentiated not only by prices, but also by quality controls, after-sale support, and customization services.

| Manufacturer | Hardness (HRC) | Custom Dimensions | Bulk Price (USD/1,000 pcs) | Warranty |

|---|---|---|---|---|

| BuildFast Co. | 50-53 | Yes | 16 | 1 Year |

| TruGrip Industrial | 54-56 | Yes (Min. 10k) | 18 | 18 Months |

| UniSteel Corp. | 52-54 | No | 13 | 6 Months |

Customization Options for Diverse Project Needs

For sectors with unique regulatory or functional requirements, customization in steel concrete nail design becomes essential. Modern suppliers are equipped to deliver a spectrum of diameters, lengths, head designs (e.g., countersunk, flat, or round), and finishes—ranging from black oxide to heavy-duty galvanization. High-strength applications, such as bridge retrofitting or precast panel installation, may demand nails with proprietary alloy compositions that raise ultimate tensile strengths above 1400 MPa. Meanwhile, for aesthetic-focused renovations, colored powder coatings allow nails to match exposed concrete finishes.

Lead times for customized orders average 21-28 days for quantities under 500,000 pcs, while larger, ongoing supply contracts can be optimized for just-in-time delivery models. Engagement with technical consultants ensures that fastener performance aligns precisely with substrate conditions, load expectations, and environmental exposures.

Case Studies: Applications of Steel Concrete Nail

The versatility of concrete steel nail solutions is reflected in successful projects worldwide. In a recent metropolitan subway extension, the selection of galvanized steel concrete nails halved installation time for cable holdfasts, reducing overall electrical works from 12 days to 6. Load testing confirmed anchorage strengths of 1.6 kN per fastener, exceeding local code by 23%.

In another case, a logistics distribution center in northern Europe employed custom-length nails to attach wall panels to pre-stressed slabs. Here, the error rate over two million fasteners was below 0.7%, and zero deformities were observed under cyclic loading trials. In smaller retail renovations, contractors reported savings equivalent to $0.12 per square foot through reduced labor and material waste, a critical margin contributor for such operations.

The Future of Nail Through Concrete: Trends and Commitment to Quality

As construction projects scale in complexity and regulatory demands intensify, the need for reliable nail through concrete solutions continues to grow. Material science innovations and enhanced process controls are steadily raising the bar for performance and sustainability. Today, over 65% of major infrastructure projects specify certified concrete steel nail products as their default anchoring method, a trend expected to accelerate as green construction practices shift focus to product lifecycle and recyclability. Investing in tested, versatile fasteners is now not just a practical choice, but a vital component in ensuring long-term structural integrity and cost efficiency for every project phase.

(concrete steel nail)

FAQS on concrete steel nail

Q: What is a concrete steel nail?

A: A concrete steel nail is a hardened steel nail specifically designed to penetrate concrete surfaces. Its composition and shape allow it to drive into hard materials without bending. These nails are essential for construction and carpentry projects involving masonry.

Q: How does a steel concrete nail differ from regular nails?

A: Steel concrete nails are made from hardened steel and feature a thick, ribbed shaft for extra strength. Regular nails lack the hardness required to pierce concrete or masonry. Using a standard nail may result in bending or breaking.

Q: Can I nail through concrete using a concrete steel nail?

A: Yes, concrete steel nails are specifically engineered to nail through concrete. For best results, use the proper hammer or nail gun and ensure the nail size suits your application. Always wear protective gear when working with masonry.

Q: What tools should I use with concrete steel nails?

A: To drive a steel concrete nail, use a heavy-duty hammer or a powder-actuated nail gun. Manual hammers are suitable for smaller tasks, while larger projects may require specialized tools. Pre-drilling a pilot hole can also help prevent cracking.

Q: Are concrete steel nails corrosion-resistant?

A: Most concrete steel nails are galvanized or coated for added corrosion resistance. However, exposure to moisture over time may still cause rust. Using stainless steel variants is recommended for outdoor or humid environments.